Products >> Carbon Fiber CNC Machining >> Carbon fiber precision parts

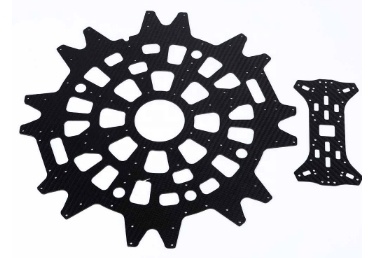

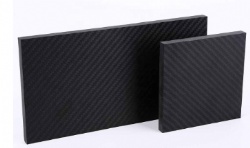

CNC Cutting 3K Carbon fiber plates

We can cut carbon fibre plates/sheets using CNC milling process.

Computer Design

We have extensive experience in 2D graphic design, we have full package of Adobe and CorelDraw. We have been dealing with vector graphics for years and this skill can be used to create designs of elements which can then be cut on our CNC router.

Cuttingelements of carbonplates using ourCNC router

We provide services to cut parts from carbon fiber plates using our own CNC router.

The router specifications

weight: approx 200 kg

construction: cast iron and cast aluminum

model: design with moving table

number of axles: 3 (X, Y, Z)

working area: 600 mm x 600 mm

Z-axis height: 200 mm

spindle: 2.2 kV

drives: servo motors 86HBM80H (torque 8 Nm) on all axes

accuracy feed: 0.03-0.05 mm

HiWin rails - square, 20mm on all axes

CNC machines with moving table structure is particularly rigid, relatively small field of work ensures the accuracy of motion in terms of the entire area of the field work, backlash-free, square HiWin rails along with very strong and accurate servo motors assure that cutting elements will be exactly the same as on the drawing.

We can cat one single element or do mass production.

What is CNC cutting

A CNC router is a kind of milling machine, in which the tool - cutter (end mill), mounted in the spindle rotates. Servo motors move the table or spindle via special ball screws, which convert the rotary motion to sliding. The spinning end mill at a speed of several or tens of thousands of revolutions on cuts through the surface of a carbon fibre plate and starts filing the plate. In fact, it is the process of milling.

Cutters - End Mills

We use end mills with diameter of 2 mm. Smaller diameter cutters quickly wear out, thicker cutters are not capable of cutting smaller holes, so we decided to use cutters 2mm and we can cut holes as small as 2mm. Of course, we can also use smaller or larger diameter cutters.

2 mm end mills, however, are not large, and their life span is not long since the carbon fibre plates are one of the hardest materials. Consequently, in order to maintain cutting quality we need to change the cutters often. The price of cutters varies depending on the type between 3 Euro to around 8 Euro each. This, unfortunately, leads us to additional costs. We do not refuse to cut out even a single element - this is what our service is for, but to preserve the quality of cutting we have to use sharp cutters. We have decided that a portion of the costs associated with the preparation of the machine and the material will be devoted to the frequent exchange of cutters. Therefore, we will not add any additional fees to the price of the cutting service, but to make sure the cutting edges of your elements are perfect you may wish to pay an extra fee for a new cutter that we would use to cut your plates.

Products Category

- Carbon fiber forged pattern business card holder

- Carbon Fiber CNC Machining

- Carbon fiber ornament

- 3K carbon fiber plain cloth

- Carbon fiber board processing engraving

- L form carbon fiber reinforced composite polymer

- CNC carved carbon fiber composite keyboard

- Carbon fiber pipe

- Profiled carbon fibre tube

- Carbon fiber accessories for medical instruments

- Carbon Fiber Product

- Carbon Fiber Sheets

- Custom Carbon Fiber

- Carbon Fiber Shaped Parts

- Carbon Fiber Pultrusion Products

- Carbon Fiber Car Modification

- Carbon Fiber Bicycle Frame

- Carbon fiber UAV accessories

- Carbon Fiber Robot

- Carbon fiber accessories for fitness equipment

Contact Us

Name: joe

Tel: +86-18900777896

E-mail: [email protected]

Whatsapp: 18900777896

Add: 22F, Hisense building, Chuangye Road, Nanshan District, Shenzhen city, Guangdong province, China

CHINESE

CHINESE ENGLISH

ENGLISH

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry